MHM BRINE INJECTORS

Designed for brine injection of meat, with bone or boneless, meat products, whole

Poultry and poultry parts, fish and fish fillets.

Advantages:

- low and high injection levels

- Smooth regulation of the speed of the head and the conveyor as standard (in the MHM 21 model - optional)

- Intuitive touch screen control panel

- Uniform distribution of brine

- highly efficient centrifugal brine pump made of stainless steel

- smooth brine pressure control

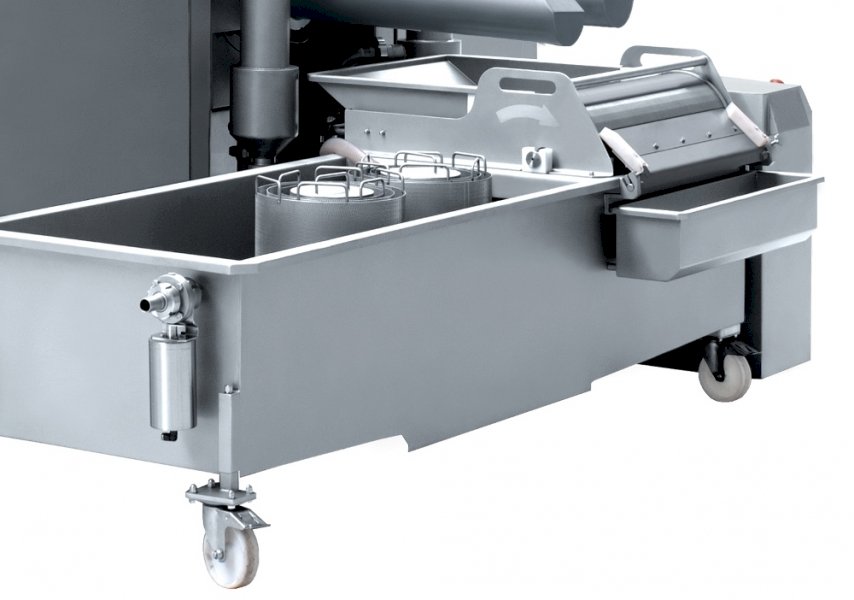

- function of mixing and pumping out the brine from the tank (for the FBN rotary filter)

- helical pump for heavy brine (optional)

- closed brine circulation system

- easy to clean multistage brine filtration system