Industrial vacuum cutters - bowl cutters - Even better for the production of homogenized meats and.all types of meat stuffing with different degrees of grinding and for fat emulsions. They are also used in the fish, confectionery, fruit and vegetable industries, as well as for the production of ready meals and pet food. They are designed for medium and large processing plants.

Construction advantages:

- stainless steel construction

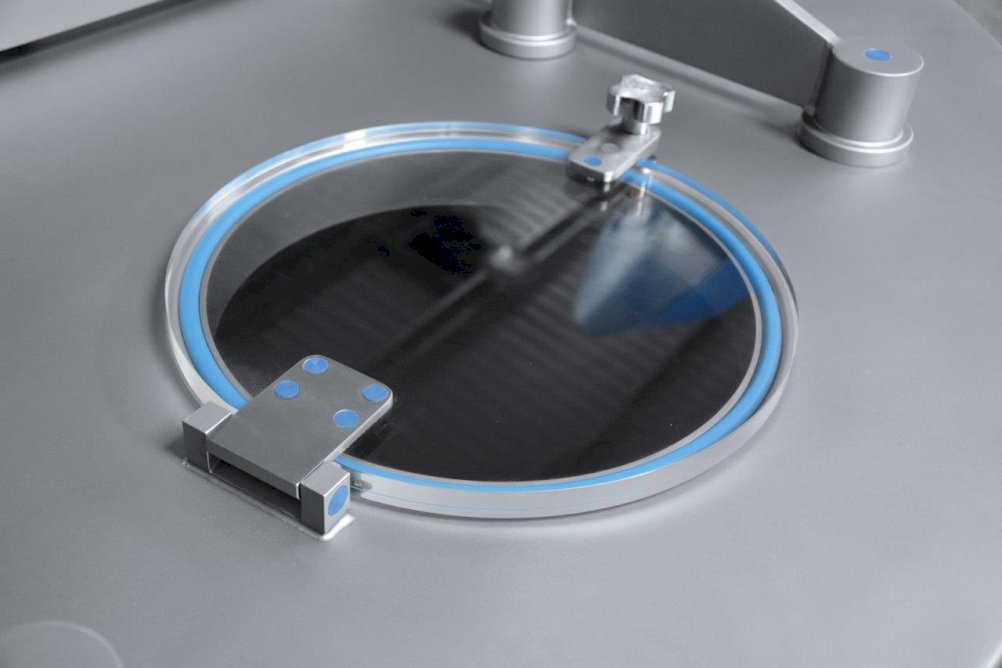

- cutting in vacuum environment – max. 90%

- high quality and repeatability of stuffing production

- high production efficiency per hour

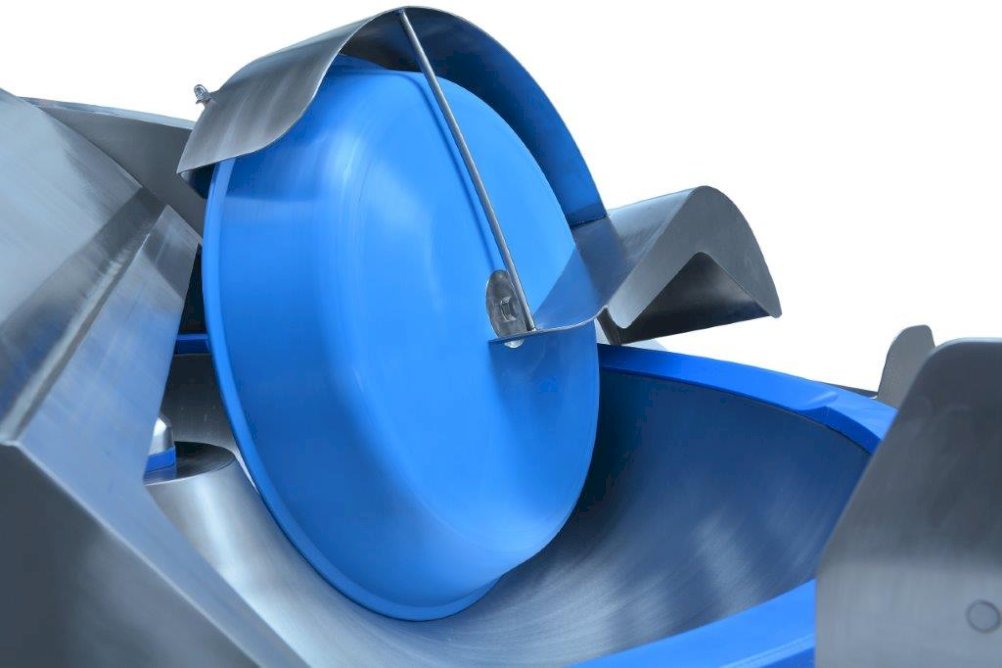

- optimal shape of the cutting chamber in combination with the shape of the knives

- equal stuff crumbling in all the bowl’s volume caused by “cutting in the air”

- microprocessor control system

- smooth control of the cutting and mixing rotations

- smooth control of stuffing unloader rotations

- versatility: besides cutting, mixing of stuffing is also possible

- possibility of programming up to 40 technological programs

- possibility of changing the language of operator panel

- current monitoring system of machine’s operation, auto diagnostics and sound signaling system

- high-speed rotation of knife head (cutting rotations)

- hydraulic loading system for the 200 ltr. buggies

- easy unloading with the use of stuffing unloader controlled by the joystick

- hydraulically operated front and back covers of the bowl

- automatic water dosage system (optional)

- head with cutting knives not requiring regulation of distance from bowl

- head with 8 knives (optional)

- cutting chamber with compartment for salami (optional)

- stuffing temperature control

- easy access to all cutter’s elements during the washing after opening the front cover

- check opening hole in the lid

- construction meets the highest hygiene requirements (flat surfaces inclined at an angle of 3 degrees)

- automatic central lubrication system

- product contact surfaces are polished

- online diagnostic system via the Internet

- complete work safety system