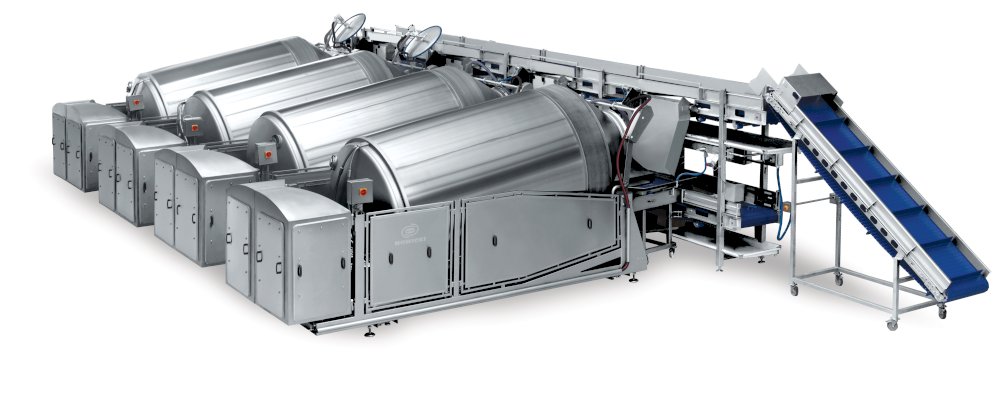

NOWICKI automatic defrosting line Metalbud Nowicki has launched in the USA an automatic line for defrosting meat used in the production of burgers.

- The line has been designed strictly according to the customer's needs, based on raw material frozen in blocks.

- Specially designed tumblers with a capacity of 12,200 l are equipped with blades, which shape enables smooth movement of the blocks and does not damage the defrosted meat.

- The unique system of heating and cooling jacket, as well as steam injection gives full control of the temperature inside the drum and allows to shorten the defrosting time to a minimum while maintaining high quality of the defrosted raw material.

The tumblers are equipped with the advanced - automatic - loading and unloading system

- The loading and unloading operations are controlled from the tumblers control touch panels.

- The parameters of the defrosting process were programmed for 6 - hour process for beef trimming frozen in blocks. The obtained raw material is used for the production of burgers.

- The line of 4 tumblers is designed for continuous operation in a three-shift system. • According to the customer's requirements, the line can defrost 40 tons of beef daily from -20oC to -4oC.

- The line is simple and safe to use as well as fully hygienic.

- It is universal line which can be used to defrost individual muscles or raw material pre-minced by the grinder as well as for other processes such as massaging or marinating