BUGGY WASHER MWF

The machine consists of a washing and rinsing chamber and loading and unloading device.

Water circulates in closed filtered cycle. A possibility of adjusting the amount of rinsing water guarantees a satisfactory level of total water consumption.

- Stainless steel washing pump

- Water heating systems: electric, steam, electric-steam, gas and oil

- Rotating washing arm

- Automatic chemical dosing

- Rotary filter (in MWF-2 as a standard)

- Multistage protection system during realization of a process

- Loading and unloading device

- Closed water circulation with filtration system

- Control of rinsing water consumption

- Steaming (optional)

- Touch screen panel - full adjustment and control of washing process for each individual operation

- Electronic detergent dosing system precisely controls process of adding of washing agents during the washing cycle

- compact construction with safety guards and photocells system ensures max. safety for operating personnel during the machine's operation. By applying rotating arm with washing nozzles it is possible to achieve capacity up to 60 buggies (MWF-1) and 90 buggies (MWF-2) per hour, at very careful washing of all buggy surfaces - also the bottom of the buggy and its wheels

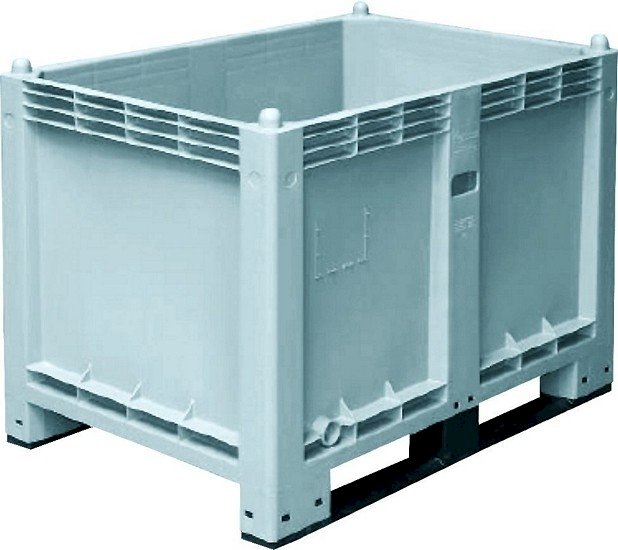

BOX PALLET WASHER MPD-1

Chamber type designed to wash 30 dolav containers per hour (of 1200x1000x800 mm max. dimensions).

As one of the first companies in the world, Nowicki has introduced an effective solution to clean all walls of pallet boxes, as well as their bottoms, it is an innovative system of a rotating basket. This system swirls the washed element (box pallet), which is treated with cleaning agent on each side. This design allows very thorough cleaning of the box-pallet and the discharge of excess water before opening the chamber.