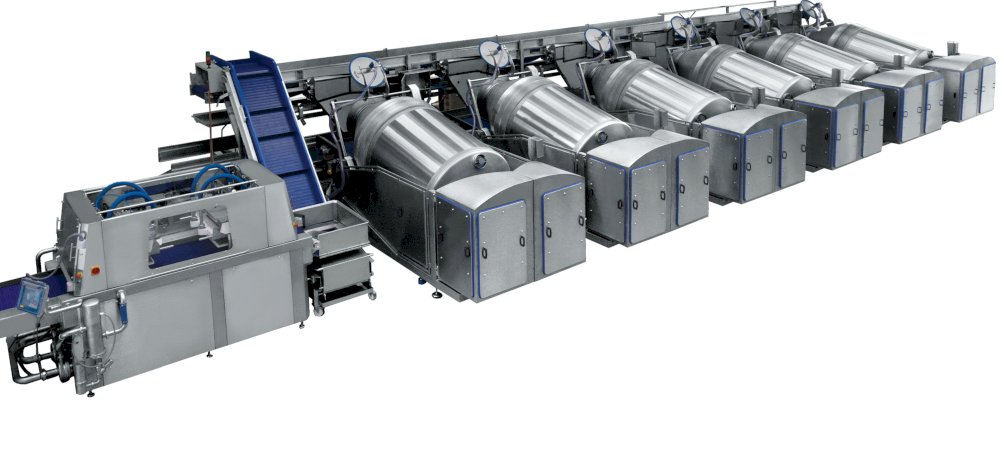

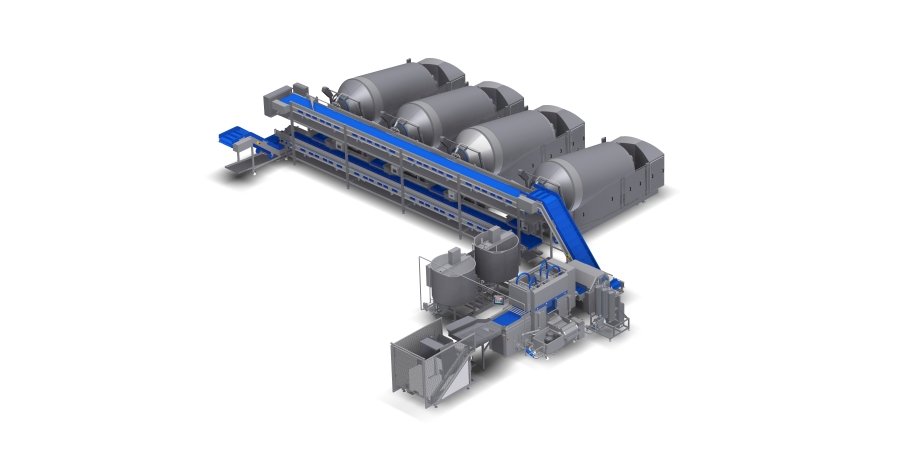

FULL AUTOMATION OF MASSAGING AND / OR DEFROSTING PROCESSES

Elimination of the human factor and significant reduction of process costs due to modern transport, loading and unloading solutions

Technological advantages

- minimization of treatment times

- possibility of the significant reduction of inter-operational losses

- simple operation

- eliminating the possibility of personnel errors

Construction

- completely made of acid resistant steel

- easy access to all line elements

- reinforced elements, when working with frozen blocks

Automation of processes thanks to an advanced control system

- full control and automation of each stage of the process (loading, weighing the load, massaging / defrosting, temperature, unloading)

- all the technological steps for the whole line are programmed and controlled from the central panel

- additional, independent control at each machine

- Internet diagnostics system and registration of all online process parameters

Loading system

- possibility to work with a belt or mechanical loading system

- specially adapted for loading frozen meat blocks