INJECTORS MH-424 W SAS with an integrated weighing system

- high repeatability of the injection level

- continuous monitoring of any deviations in the injection level and the possibility of their immediate correction

- identification of errors in the injection process resulting from human factor or technical problems (e.g. incorrect brine or raw material temperature, incorrect program parameters)

- information about machine downtime

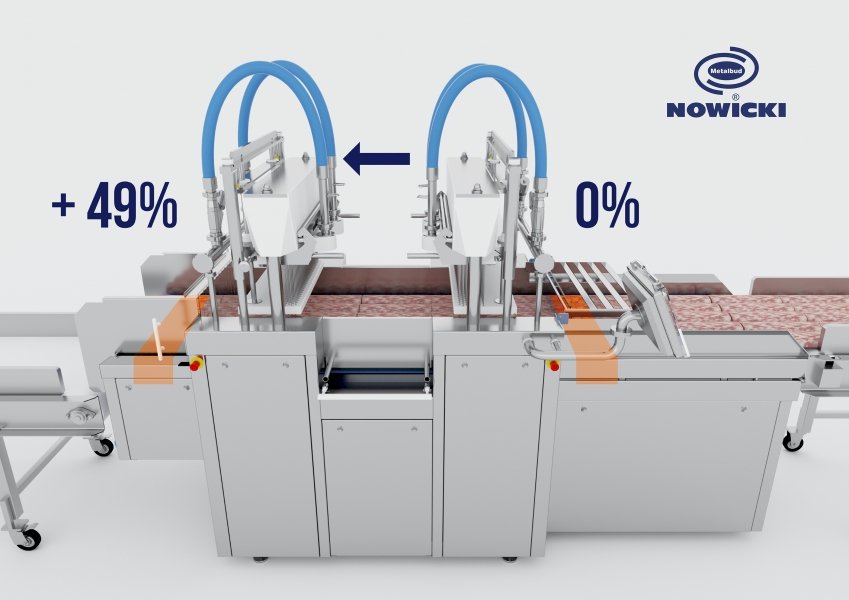

The weighing system with SCADA monitoring give the possibility of full control of the injection level

- two measuring systems located at the beginning and the end of the injection zone, continuously measure the weight of the raw material on the machine conveyor

- the advanced control system shows the current percentage increase in the weight of the raw material on the basis of the difference in indications

- the dynamic weighing system enables to control the injection level giving the operator the possibility of any adjustments in the program to maintain the set injection level for the whole lot, thus eliminating inaccuracies resulting from the quality of individual muscles, temperature, etc.

- full product control in terms of appropriate final product composition, compliance of the composition with the label and economic effect

- compact design - weighing system integrated into the machine (no external weighing tables)

SAS SYSTEM INJECTORS (Servo Automatic System)

are intended to implement the most advanced processes of injection covering a wide range of meat raw materials:

- muscles and elements of red meat with bone or boneless

- whole poultry and parts of white meat with bone or boneless

- fresh meat - white and red

- fish and fish fillets