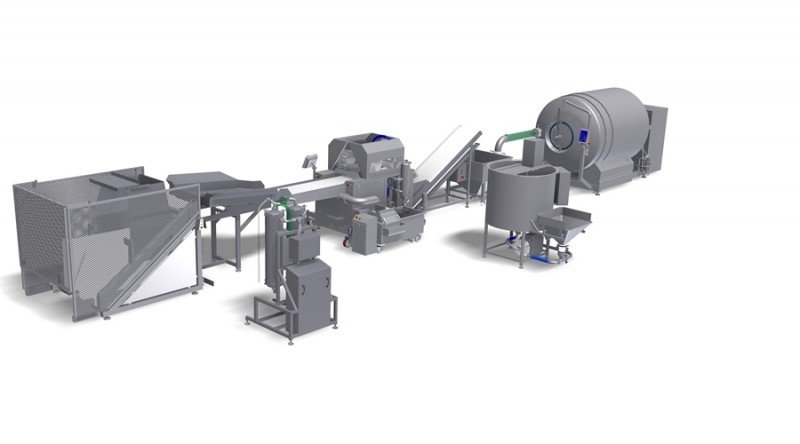

Fully professional line for industrial injection of chicken breast, chicken nuggets and chicken-strips.

As per growing demand from producers working in cooperation with Fast Food Chains and producers of Convenient Food – Metalbud Nowicki has entered the market with its automatic lines for industrial injection of boneless meat.

Operation and supervision by one person allows the production of about 1,5-2 tons of chicken products per hour, meeting the highest demands from Customers. Low factory footprint, efficiency and low maintenance costs squeeze out extra percentages as a profit for producers, making all production more profitable.

Line configuration can be widely tailored to producer needs, overall giving them many different options in terms of loading, injection yields, conveyor systems, tumbling and brine management.

As the main line component there is the newest generation of injectors type MH-660 SAS and MH-1480 SAS driven with servo drive. One of their most important advantages is extremely close needle pattern allowing for an equal injection even in the smallest pieces of meat. That ensures the high production repeatability. Injector construction makes extremely quick brine flow from pump to needle tip without any restriction on brine flow – that gives the best results in constant brine pressure and eliminates sources of contamination. Stable injection is enhanced by constant brine temperature during injection. 2 - 2,5 mm needles reduce to minimum the marks on meat surface.

High and low injection levels.

Extremely high process repeatability.

Process can be monitored via SCADA monitoring system!

Everything under your control – working to maximize profit during production!

The whole line consists of:

- Loading from Europallets or regular 200 ltr trolleys onto a long infeed-side injection belt

- Injection with Servo Drive injector with 660 or 1,480 needles and short injection stroke.

- Conveyors for a 3,000 litre vacuum loading tank

- Loading tank connected to the vacuum tumbler.

- Vacuum tumbler (with sizes up to 10,200 litres), tilted or horizontal, to be filled either by vacuum or by conveyor. Tumbler cooling system can be connected to factory’s cooling network.

- Brine system for : preparation of brine, supply of brine into rotary filter, chilling down of brine during preparation and ensuring a constant temperature during injection.