Designed for grinding fresh and frozen meat down to -20 o C to required granulation and making other technological operations depending on used equipment.

The grinders have a wide range of applications in the industry:

- Meat processing

- Processing of fish and seafood

- Pet-food, convenience food

- Fruit and vegetable

- Confectionery

Construction advantages:

- high quality execution of stainless steel

- high quality of ground product

- execution of pressing chamber and pressing worm in highly resistant to abrasion stainless steel

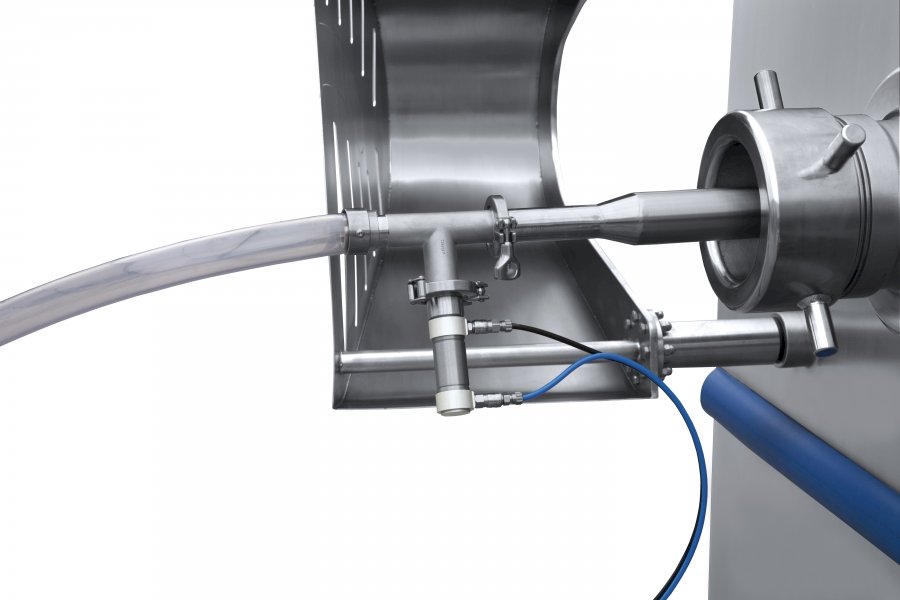

- two compatible drives of feeding worm and pressing worm ensure optimal adjustment of amount of dosed material

- smooth regulation of feeding worm (optional)

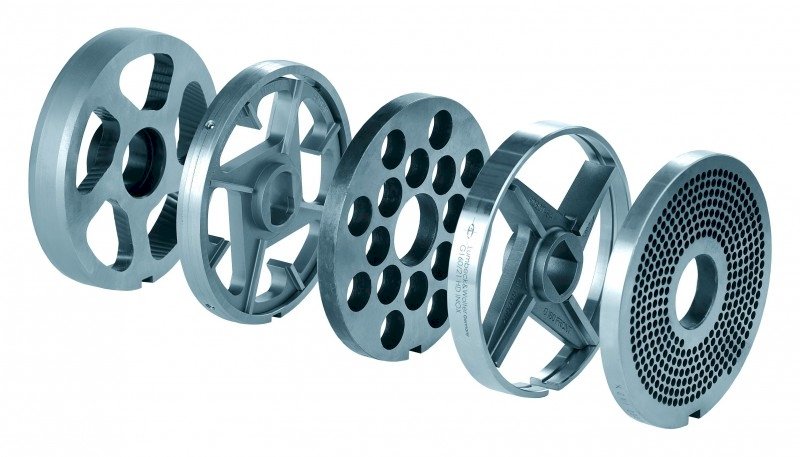

- cutting system includes high quality cutting devices

- automatic adjustment of material feeding to set load of pressing worm

- pressing worm equipped with an automatic pushing out system (option W-160, W-200)

- grinders equipped with peripheral device for separation of tendons and membranes (option) and separator of poultry bones (option)

- safety systems for optimum working safety

- microprocessor controller responsible for control of all work parameters

- the pressing worm is made of single metal element without a welding process

- grinding system for frozen meat blocks (-20 o C) (optional)

- special execution of grinders for frozen fish blocks

- adjusted for various types of loading

- easy to clean